Mold and die making is the sculpture wing of CNC manufacturing. Every job is different, surfaces are complex, and tolerances are unforgiving. The workflow ranges across roughing blocks, finishing cavities, cutting electrodes, machining inserts, and fitting assemblies. Because it’s custom work, many mold shops accept custom fixturing as a fact of life. But as lead times tighten, that assumption becomes a liability.

The most competitive mold makers are not necessarily the ones who cut the fastest. They’re the ones who flow the fastest — moving work through multiple ops and multiple machines without losing datums or time.

That speed comes from platform workholding.

The mold workflow problem

Mold jobs typically involve:

- multiple setups per insert

- frequent inspection

- transfers between machines

- re-clamping after EDM or polishing

- high rework cost for any misalignment

If each step requires fresh indicating and manual alignment, you burn time on “setup labor” instead of cutting plastic-ready geometry.

Platform workholding changes the game

Platform workholding is a simple concept:

make the machine interface standard, and make fixtures modular.

Instead of building a full custom fixture for every insert, you standardize the baseline. Fixtures become top modules that dock into a repeatable system. That yields two mold-specific advantages:

- Datum preservation across ops

- Offline electrode and insert presetting

In practice, many mold makers standardize their datum transfer using modular zero-point families such as 3r systems, which allow inserts and electrodes to move between milling, inspection, EDM, and back without reinventing their coordinate system.

Electrodes: where platform workholding shines brightest

Electrodes are the mold maker’s “other half.” They are delicate, time-sensitive, and notoriously vulnerable to datum drift.

With a repeatable platform:

- you machine electrodes on one setup

- inspect them

- dock directly into EDM referencing the same datum

- return if needed without re-zero

This reduces EDM mismatch and saves huge alignment time.

Inserts and cores: faster multi-op flow

Core and cavity inserts often require:

- rough milling

- semi-finish

- inspection

- finish milling

- hand finishing

- re-inspection

- possible revisit after fit-up issues

Every revisit is expensive if the fixture must be rebuilt or re-indicated. With a modular platform, revisits become trivial: dock, verify, finish.

The clamping layer still matters

Platform workholding makes datums repeatable — but clamping still decides whether the part stays stable while cutting.

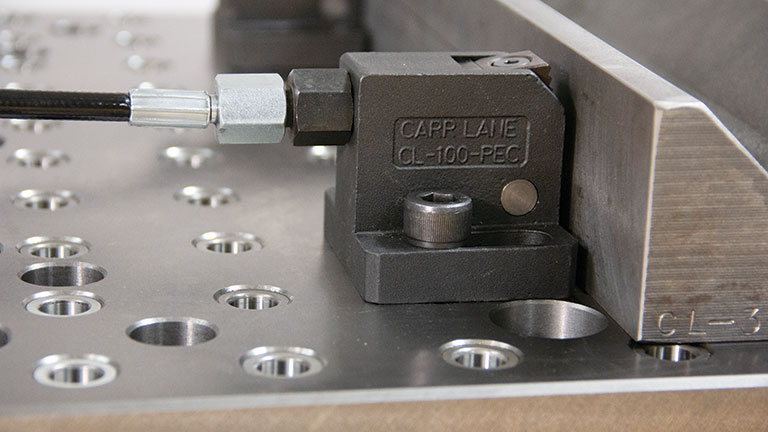

For many prismatic mold components and electrode blanks, symmetric clamping is ideal because it reduces skew and makes center location predictable. That’s why a lot of mold shops pair their platform baselines with self-centering clamps or vises such as CNC Self Centering Vise, which speed blank prep and cut down first-article adjustments.

Quality benefits mold shops feel immediately

Mold work is sensitive to:

- cavity mismatch

- insert height drift

- electrode offset errors

- surface re-blending after rework

Repeatable baselines reduce each of these. The benefit isn’t only time saved; it’s the removal of geometric risk that causes late-stage surprises.

How to convert without rebuilding everything

Platform upgrades in mold shops should be incremental:

- start with electrode presets

- then convert your highest-repeat insert families

- build a small offline preset station

- spread to additional machines

You don’t need to throw away old fixtures. You retrofit their bottoms to the new baseline.

Closing thought

Platform workholding is the bridge between custom craftsmanship and modern speed. It lets mold shops remain flexible while acting repeatable. That combination — flexibility plus repeatability — is what cuts real lead time and protects margins in today’s mold market.