External cylindrical grinding is one of the most widely used machining processes for shaping and finishing metal components. It plays a vital role in manufacturing industries where high precision, tight tolerances, and smooth surface finishes are required. This process employs an external cylindrical grinder, a specialized machine designed to remove material from the outer surface of a rotating workpiece. Understanding the techniques, methods, and applications of external cylindrical grinding is essential for machinists, engineers, and manufacturers aiming to achieve optimal efficiency and product quality.

Understanding External Cylindrical Grinding

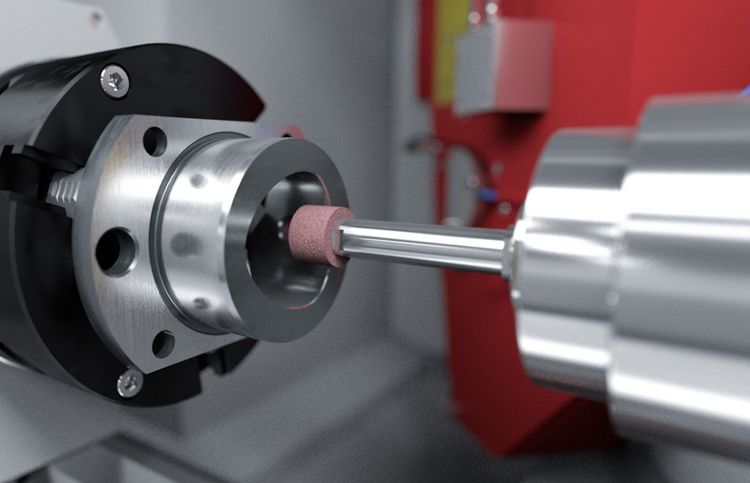

External cylindrical grinding is a machining process in which a workpiece is rotated and brought into contact with a rotating grinding wheel. The abrasive action of the wheel removes small amounts of material, gradually refining the surface until the desired diameter, geometry, and finish are achieved. This process is used to machine parts such as shafts, rods, spindles, and bearing journals. Unlike other machining methods, grinding can produce extremely fine finishes and precise dimensions, making it indispensable in industries such as automotive, aerospace, energy, and tooling.

The external cylindrical grinder is the central machine in this process. It consists of a grinding wheel mounted on a spindle, a workholding mechanism such as a chuck or centers, and various controls to adjust speed, feed, and depth of cut. Advanced models may include CNC controls, automation, and in-process gauging systems for enhanced accuracy.

Types of External Cylindrical Grinding

Plain Cylindrical Grinding

Plain cylindrical grinding involves mounting the workpiece between centers and rotating it while the grinding wheel removes material. This technique is suitable for parts with uniform diameters and is commonly used for shafts and rods.

Universal Cylindrical Grinding

Universal cylindrical grinding is more versatile and allows the grinding of both external and internal surfaces. The external cylindrical grinder used in this method has additional attachments that enable taper grinding, internal bore grinding, and other complex shapes.

Centerless Cylindrical Grinding

Centerless grinding eliminates the need for centers or chucks. Instead, the workpiece is supported by a blade and guided between a grinding wheel and a regulating wheel. This method is highly efficient for producing large volumes of small cylindrical parts with excellent accuracy.

Creep Feed Grinding

Creep feed grinding is used for deep cuts where a large amount of material needs to be removed in a single pass. It requires specialized machines and wheels but offers high efficiency and productivity.

Key Components of an External Cylindrical Grinder

- Grinding Wheel: The heart of the machine, usually made from abrasives like aluminum oxide, silicon carbide, or cubic boron nitride (CBN). The choice of wheel affects cutting performance, finish, and tool life.

- Workholding System: Centers, chucks, or collets hold the workpiece securely in place during grinding. Precision alignment is crucial for accuracy.

- Spindle: Rotates the grinding wheel at high speeds. The rigidity and balance of the spindle directly impact surface finish.

- Tailstock: Provides support for the opposite end of the workpiece, ensuring stability during machining.

- Machine Bed: A stable base that absorbs vibrations and maintains alignment.

Techniques for Effective Grinding

Selection of Grinding Wheel

Choosing the right grinding wheel is fundamental. Factors include abrasive type, grit size, bond material, and wheel hardness. Coarse grit wheels are used for heavy stock removal, while fine grit wheels achieve smooth finishes.

Proper Dressing of the Wheel

Over time, grinding wheels lose their sharpness due to loading or glazing. Dressing restores the cutting ability of the wheel and ensures consistent performance. Diamond dressers or rotary dressers are commonly used.

Control of Speeds and Feeds

Workpiece speed, wheel speed, and feed rate must be optimized for each application. Too high a speed may cause burning or chatter, while too low a speed can reduce efficiency. Balancing these parameters ensures precision and productivity.

Coolant Application

Coolants reduce heat generation, minimize thermal damage, and extend wheel life. Proper coolant selection and delivery are essential to prevent workpiece distortion and maintain surface quality.

In-Process Measurement

Modern external cylindrical grinders often incorporate gauging systems to measure dimensions during grinding. This reduces scrap rates and ensures that tolerances are maintained consistently.

Common Challenges and Solutions

- Chatter Marks: Caused by vibrations. Solutions include improving machine rigidity, balancing the grinding wheel, or adjusting speeds.

- Burning of Workpiece: Excessive heat can alter material properties. Using the right coolant flow and optimizing wheel parameters prevents burns.

- Wheel Loading: Occurs when material clogs the abrasive surface. Frequent dressing helps maintain wheel sharpness.

- Out-of-Roundness: Can result from improper alignment or workholding. Careful setup and calibration of the machine eliminate this issue.

Applications of External Cylindrical Grinding

External cylindrical grinding is widely applied across industries:

- Automotive: Grinding crankshafts, camshafts, and gear shafts to precise tolerances.

- Aerospace: Machining turbine shafts, landing gear components, and precision connectors.

- Energy: Producing pump shafts, generator rotors, and other heavy-duty parts.

- Medical Devices: Manufacturing surgical instruments and orthopedic implants.

- General Engineering: Creating tooling, dies, and machine spindles with exact geometries.

Advantages of Using an External Cylindrical Grinder

- High precision and repeatability

- Ability to achieve very fine surface finishes

- Capability to handle hardened materials that are difficult to machine conventionally

- Flexibility in producing cylindrical, tapered, and contoured surfaces

- Cost-effectiveness for high-volume production

Best Practices for Operators

- Regularly inspect and maintain the machine to avoid unexpected breakdowns.

- Ensure correct wheel mounting and dressing before every job.

- Use appropriate safety gear including goggles, gloves, and protective clothing.

- Keep the workspace clean and free from grinding dust.

- Continuously monitor workpiece dimensions to maintain tight tolerances.

Future Trends in External Cylindrical Grinding

With advancements in technology, external cylindrical grinders are becoming increasingly sophisticated. CNC control systems enable automated operations with minimal human intervention. Adaptive control algorithms adjust parameters in real time for consistent quality. The use of superabrasives like CBN and diamond wheels extends tool life and allows machining of ultra-hard materials. Integration of IoT and Industry 4.0 concepts ensures predictive maintenance and real-time monitoring of grinding processes. These innovations not only enhance productivity but also reduce waste and operational costs.

Conclusion

External cylindrical grinding remains a cornerstone of modern manufacturing. Its ability to deliver high precision, superior surface finishes, and consistent results makes it indispensable across diverse industries. By understanding the techniques, components, challenges, and future trends, manufacturers can fully harness the potential of this process. Investing in a high-quality external cylindrical grinder, selecting the right grinding techniques, and adhering to best practices ensures that businesses achieve maximum efficiency, reduced downtime, and exceptional product quality.